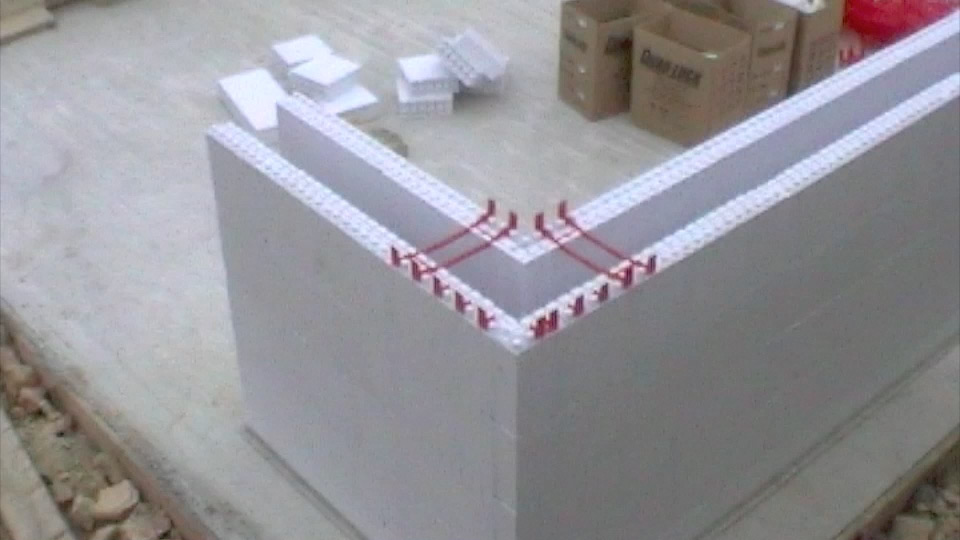

Quadlock - ICF Concrete System

ICF systems are extremely fast – the air tightness of the completed structure is unmatched by any other form of construction, the 220mm of expanded polystyrene insulation stays in place, no wasted material like traditional timber shuttering.

There is a very good video of the ICF (Insulated Concrete Forms) on the Quadlock website – showing how quickly this went up. It took us just under two days, 2 people to lay a structure 40m long, 7m wide, 3m high with a second staging 5.5m high – a day later, and just 3 hours of concrete pumping the basement was finished. Enough said – ICF systems are extremely fast – the air tightness of the completed structure is unmatched by any other form of construction, the 220mm of expanded polystyrene insulation stays in place, no wasted material like traditional timber shuttering.

There are many other ICF systems now on the market Polysteel, Quadock, Logix, Polarwall. Air tightness levels of these ICF systems is often 1.96m3/hr/m2 @ 50pa far exceeding the most stringent Swedish design bench mark of 2.88m3/hr/m2 at 50pa – our building regs presently state 10m3/hr/m2 @ 50pa. I find it very hard to recommend Beco-Wallform – the difference here is how they rely on the strength of the polystyrene to keep the two walls together, having seen 3 sites where blow outs occurred I would need some serious convincing to use their product. Also when you finally come to clad your walls in plasterboard or similar you need a fixing – Quadlock has the advantage of very strong plastic ties that you can screw directly in. Although most systems use expanded polystyrene, Polarwall is manufactured from extruded polystyrene which firstly has a much lower thermal conductivity of 0.027 compared with expanded at 0.040W/mK. So for 200mm you get a U value of 0.13 compared with Expanded Polystyrene of 200mm thick U value of 0.2 W/m2K. It’s not just the thickness of insulation which is important, but the quality or thermal conductivity of he material you are using.

The floor wall joint – the dry joint caused between the concret basement slab and the vertical walls yet to be poured. This is the main weakness of these ICF systems, in hind sight the best detail would be to pour the slab with a 150mm or more upstand or form the wall so that you have no weakness at the 90 degree angle – this would be difficult to created but is feasible. Instead we put down a slurry mix of compact Civil All on concrete painting it over the whole joint and then adding a water bar, a flexible product that expands in contact with water filling any voids – shouldn’t be necessary but created a very robust detail – which of course never leaks – or so they say. The real secret is to make sure you have a good wet free flowing concrete that is well vibrated – so you have no air bubbles or pockets of concrete. By letting the concrete pour forward – roll forward, the weight expels any voids or air pockets, buy letting the concrete fall vertically then there is the risk of voids. Phil Sacre of //www.waterproofconcrete.co.uk/ has lots of useful tips and many years of experience gained from his own personal mistakes – well worth a visit.

Websites: